Synchronous electric clocks are a very different beast from their mechanical ancestors. They don’t rely on escapements or oscillators, and nothing is ticking inside them in the traditional sense. Instead, they make use of the frequency of the AC mains power supply—50 cycles per second in much of Europe, 60 in North America. That frequency becomes the clock’s heartbeat. A small synchronous motor turns in phase with the grid’s oscillations, and this motion drives the gear train, which moves the hands.

It’s a simple but clever idea. And it arrived at just the right time—during the early decades of the 20th century, when electrification was spreading rapidly across towns, cities, and eventually rural areas. Power grids were maturing, alternating current had become the standard, and utility companies were beginning to take frequency regulation seriously. It was no longer wild and variable—it was becoming dependable enough to build a clock around.

Quartz didn’t just keep better time—it changed what time meant to people.

-Kev Green

The first truly successful attempt to do just that came from an American engineer named Henry Ellis Warren. In 1918, Warren patented a clock powered by a synchronous motor that used the grid frequency as its timekeeping regulator. His invention was granted U.S. Patent No. 1,388,306 in 1921, and it formed the basis of what became the Warren Telechron Company. The first commercially available Telechron clocks began appearing shortly after the First World War and were soon being manufactured in large numbers. Warren didn’t just design the clock—he worked with power companies to ensure the grid could support it. It was a two-part system, really: the clock mechanism and the idea that power stations needed to maintain frequency stability over 24-hour periods.

The result was that although the grid might run fast or slow for short periods due to fluctuating loads, the total number of cycles per day would be corrected. So even if a synchronous clock wasn’t second-accurate moment to moment, it would usually be bang on at the end of the day.

Meanwhile, across the Atlantic, British firms were also exploring the possibilities of electric timekeeping. Gents of Leicester and Synchronome were already well established by the early 20th century, mostly producing master-slave systems, where a central clock sent electrical impulses to keep multiple slave dials in sync. These systems were widely used in railways, factories, and schools. But they weren’t synchronous in the same sense—they didn’t rely on the grid’s frequency to regulate timekeeping. That distinction matters.

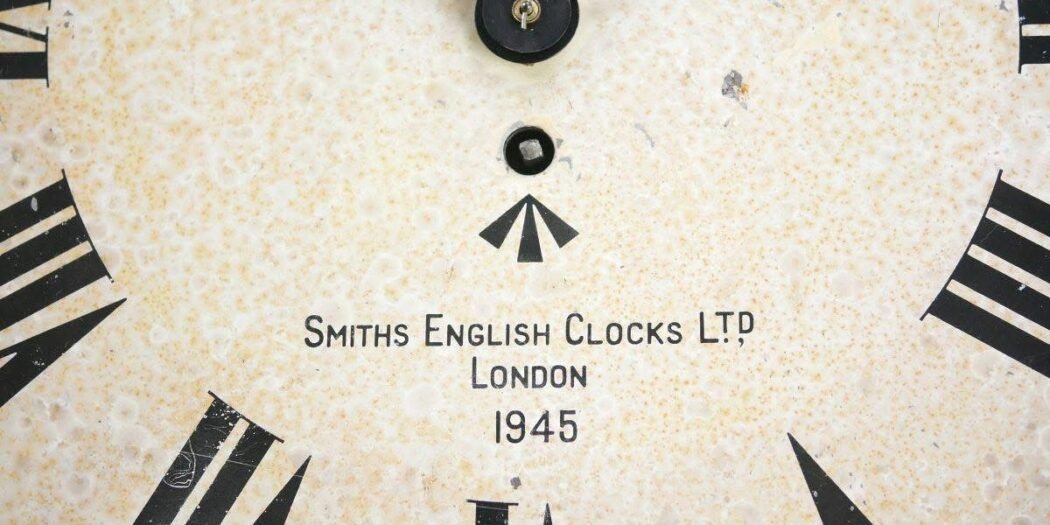

True synchronous clocks, as we now understand them, began to appear in Britain during the 1930s. Smiths English Clocks Ltd., for instance, introduced mains-powered clocks using compact synchronous motors, and these found their way into homes, offices, public institutions, and commercial buildings over the following decades. They didn’t need winding. They didn’t drift badly. And they were remarkably low-maintenance.

Cost was one of the big selling points. Because these clocks didn’t require finely tuned escapements or complicated mechanical regulators, they could be manufactured relatively cheaply. Once the motors and gear assemblies were being produced at scale, it became possible to offer electric clocks to the public at prices comparable to or even lower than wind-up alternatives. In the United States, a basic wall clock from Telechron in the 1930s might cost two or three dollars—somewhere in the ballpark of $40 to $100 in today’s money. Models with decorative cases or additional features could go higher, but even then, they remained within reach of the middle-class consumer.

Accuracy wasn’t observatory-grade, but it didn’t need to be. Over a typical 24-hour cycle, a well-maintained power grid could keep a synchronous clock within 30 seconds of true time, and often much better. That level of performance, coupled with a complete absence of winding or adjustment, made these clocks ideal for homes, offices, schools, and stations.

30 seconds of true time, and often much better. That level of performance, coupled with a complete absence of winding or adjustment, made these clocks ideal for homes, offices, schools, and stations.

The bigger impact came from their uniformity. Synchronous clocks in a single building, all plugged into the same mains supply, would stay in sync to the second. In schools and factories, this meant coordinated breaks, shift changes, and bell rings. In offices, everyone arrived, departed, and scheduled meetings to the same minute. Even across towns and regions, as long as the power came from the same grid, clocks agreed. For the first time, timekeeping began to feel not just accurate, but shared.

This wasn’t just a technical development—it was a quiet cultural shift. No longer did you have to adjust for the quirks of your mantel clock or check the town hall tower to confirm the hour. Your kitchen clock, your office clock, the one above the train platform—they all sang from the same hymn sheet, because they were running off the same signal. The electrical grid had become a new kind of timekeeper.

Technically, what made this possible was the synchronous motor itself. The earliest designs used shaded-pole motors, where copper rings delay part of the magnetic field to generate rotation in a specific direction. These motors are simple, cheap to produce, and ideal for the low torque required to drive a small gear train. Once the rotor synchronises with the grid frequency, it rotates at a steady, precise speed—usually either 3,600 or 1,800 revolutions per minute in 60 Hz countries, or 3,000/1,500 in 50 Hz ones. This high-speed rotation is then drastically reduced through a series of gears to drive the hands of the clock.

Some models used a split-pole or permanent-magnet rotor with a phase-shifting capacitor for better startup reliability and direction control, especially in applications like electric timers and commercial clocks where orientation mattered. By the 1940s, these motors had become increasingly compact and efficient, leading to thinner, lighter clocks that could be hung anywhere without the need for maintenance or winding.

One of the most famous early examples was the Telechron Model 1H127, nicknamed “The Warren.” It was stylish in a 1930s kind of way—Art Deco casing, metal hands, and a small “power-out” indicator on the dial. That red dot would pop up if the power failed, reminding the user to reset the clock. It was a neat little concession to the only real weakness of the system: total dependence on the mains.

In the UK, Smiths released a broad range of electric clocks under their Sectric line, many of which remain iconic to this day. These ranged from humble kitchen clocks to elegant mantelpieces with Bakelite or walnut cases. Some used synchronised sweep seconds, others dispensed with the second hand altogether to cut noise and wear. All shared the same principle—plug in, set once, and forget.

In the UK, Smiths released a broad range of electric clocks under their Sectric line, many of which remain iconic to this day. These ranged from humble kitchen clocks to elegant mantelpieces with Bakelite or walnut cases. Some used synchronised sweep seconds, others dispensed with the second hand altogether to cut noise and wear. All shared the same principle—plug in, set once, and forget.

Factories and public buildings adopted larger versions, sometimes in combination with mechanical backup systems or impulse-controlled master clocks. The blend of technologies was fascinating. A single building might have a Smiths Sectric wall clock running from the mains, a Synchronome master system controlling bells, and a Telechron desk clock sitting quietly in the office of the foreman. Timekeeping, for perhaps the first time, had become multi-layered but harmonious.

There were challenges, of course. Frequency drift, while rare, did happen—especially during grid stress or in isolated areas with smaller generation stations. And when the power went out, the dance stopped completely. Some clocks later incorporated small balance-wheel movements as fallbacks, though these added cost and complexity and were usually reserved for high-end institutional models.

Yet despite these limitations, synchronous clocks represented something important. They weren’t just electric. They were democratic. They brought standardised time to every home with a plug socket. For the first time, nearly everyone could live to the same rhythm, not just locally, but across regions and nations.

And for all their simplicity, they were well-built. Most can still be found ticking away—or humming faintly—in antique shops and vintage electronics collections. A quick clean, a new capacitor, and they’re often good as new.

Of course, they weren’t the final step in electric horology. Another revolution was on the horizon—one that didn’t rely on the grid at all. With no need for motors or gears, and driven by vibrations far faster than any mains frequency, quartz clocks would soon render many synchronous designs obsolete.

But that’s a story for another day.

For now, it’s worth taking a moment to appreciate the gentle hum of uniformity that defined an era. These clocks didn’t tick loudly or sparkle under glass, but they changed the way we lived—quietly, steadily, and in perfect step with one another.

You can’t talk about the evolution of horology without eventually coming face-to-face with electricity. It didn’t just change how we lived—it fundamentally changed how we measured time. The story of the electric clock spans nearly two centuries, and its milestones helped shape everything from wristwatches to railway stations. Let’s walk through that journey, one quiet tick at a time.

It all starts in 1840, when a Scottish clockmaker by the name of Alexander Bain filed a patent for what we now regard as the first electric clock. Bain’s design used an electromagnetic pulse to drive a pendulum. Was it precise? Not really. Was it practical? Barely. But as with all great inventions, it wasn’t about perfection—it was about possibility.

Fast-forward to 1883 and we find ourselves in the presence of Matthäus Hipp, a Swiss engineer who wasn’t content with the early limitations of Bain’s design. Hipp introduced what became known as the Hipp toggle, an ingenious mechanism that gave a pendulum a carefully timed nudge using electrical impulses. These clocks found their way into observatories and time services, offering improved consistency and establishing the role of electricity in master clocks.

The real turning point came in 1912, thanks to an American named Henry Ellis Warren. Warren developed a synchronous electric motor—one that maintained consistent rotation by locking itself to the frequency of the alternating current (AC) in the power grid. That meant that if the grid’s frequency was stable (as it was in the U.S., at 60Hz), the clock could stay remarkably accurate without needing a balance wheel or pendulum. This was a revolution.

By 1926, Warren’s company, Telechron, had turned the invention into a household reality. Electric clocks no longer needed winding, and thanks to the power grid, they stayed in sync with the nation itself. Telechron’s designs, often Art Deco or Modernist in flavour, became as much part of American interiors as the kitchen table or telephone. And their precision meant you could trust them.

The 1930s saw electric clocks expanding well beyond the home. Factories, schools, and railway stations began using these clocks en masse, favouring the convenience and reliability of electrically synchronised systems over the fussy maintenance of mechanical ones. This period also gave birth to the so-called “master-slave” clock systems used in public buildings—one master clock controlling many others through electric pulses. The elegance of the solution was that it made entire institutions tick as one.

Things began to miniaturise dramatically in the 1950s. In 1957, the Hamilton Watch Company unveiled the world’s first battery-powered electric wristwatch—the Hamilton Electric 500. While it still used mechanical gear trains, the power source had changed from mainspring to battery. It was both a marvel and a challenge; early versions were famously temperamental, but they proved what was possible. For the first time, electricity had made its way to the wrist.

Then came the moment that would change horology forever. In 1969, Seiko released the Astron—the first commercially available quartz wristwatch. Unlike anything before it, the Astron relied on the oscillations of a quartz crystal, powered by a battery, and regulated electronically. The result? Unprecedented accuracy in an ultra-compact package. It was expensive at first, but as technology improved and prices dropped, quartz timekeeping quickly swept the world.

By the 1980s, quartz had all but taken over. Traditional electric clocks—whether synchronous or balance-wheel driven—were slowly phased out in favour of smaller, cheaper, more precise quartz options. These didn’t rely on grid frequency or pendulums. They were self-contained, durable, and most importantly, astonishingly accurate.

But the story didn’t end there. From the 2000s onward, electric clocks gained yet another layer of precision: radio control. These timepieces, often wall clocks or desk models, were built to synchronise with time signals transmitted by atomic clocks. It meant a radio-controlled clock on your wall could automatically update itself to within a fraction of a second of the world’s most accurate time standard, without you lifting a finger.

Today, electric clocks have evolved into hybrid creatures. We’ve got solar-powered quartz movements that recharge themselves from ambient light. We’ve got smart clocks that sync with satellites or your smartphone via Bluetooth. We’ve even got watches like Seiko’s Spring Drive that blend mechanical power with electromagnetic regulation. And yet, at the core of it all, the electric revolution of timekeeping started with a simple idea: that we could use invisible power to master visible time.

It’s a quiet sort of progress-no, no ticking escapement, no winding crown—but the hum of electric time has carried us into the modern world just as surely as the mainspring once did.

justaboutwatches.com

justaboutwatches.com

One comment